Video

Introduction

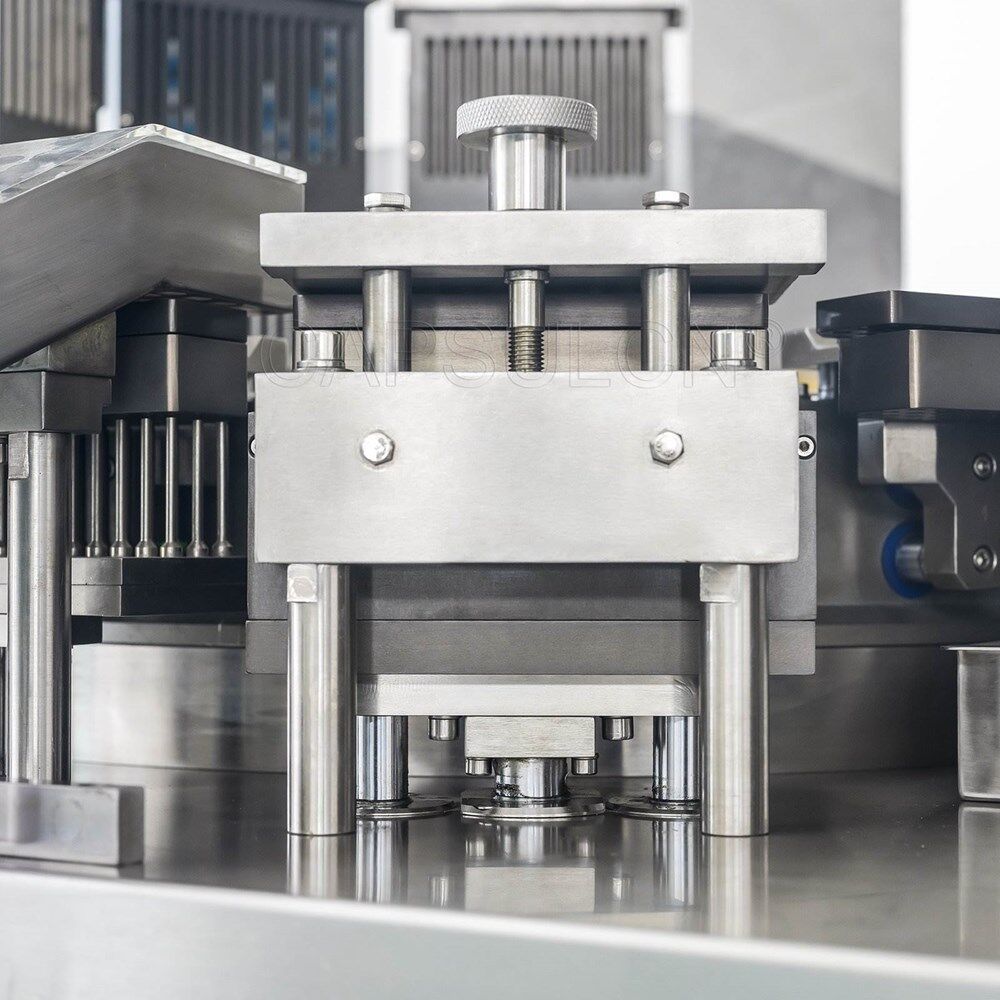

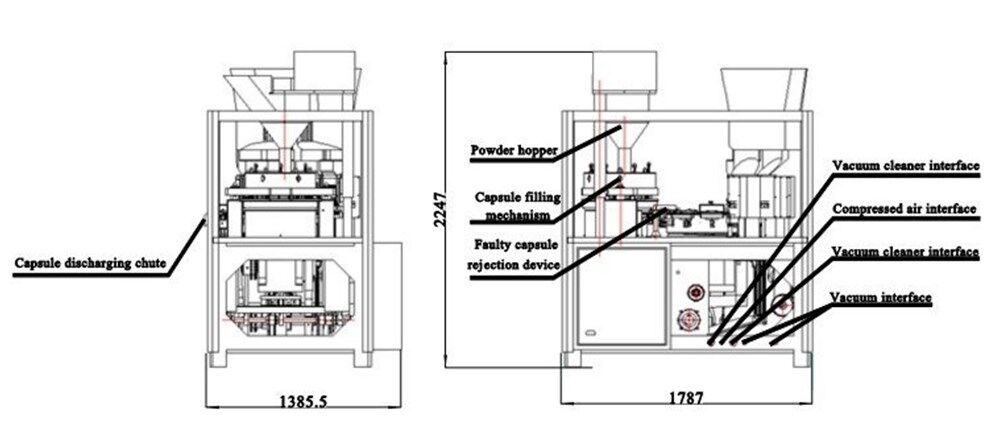

NJP-7500C automatic capsule filler processes the products for optimal productivity up to 7500 capsules per minutes, featuring low-maintenance operation, minimal downtime, and overall dependable production.

Powder dosing uses the 5 stage tamping technology for an enhanced accuracy. Filling of pellets is available.

Capsules from the bunker are fed into the orienting device along the vertical guide.

Then they are transferred into special cells on the rotor. Here the capsule is separated, after what the bottom part comes to the filling position.

After filling the bottom part with the material, on next positions the non-separated capsules are rejected, and the filled bottom parts are joined with top parts, counted and taken away into the receiving box.

Specifications

| C Type Automatic Capsule Filling Machine | ||||

|---|---|---|---|---|

| Machine Model | NJP-800C | NJP-1200C | NJP-3500C | NJP-7500C |

| Max capacity | 48,000 caps/h | 54,000 caps/h | 210000 caps/h | 450,000 caps/h |

| Suit for capsule size | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule | 00#-5# and safety capsule |

| No.of mould bores | 6 | 9 | 26 | 54 |

| Machine dimensions | 1080x1240x1930mm | 1180x1340x1980mm | 1386x1156x2100mm | 1700x1220x2150mm |

| Net weight | 800kg | 1,000kg | 2,500kg | 3,800kg |

| Power | 380/220v,50/60Hz,6kw | 380/220v,50/60Hz,6kw | 380/220v,50/60Hz,10kw | 380/220v,50/60Hz,13.5kw |

| Noise | <75dB | <75dB | <75dB | <75dB |

| D Type Automatic Capsule Filling Machine | ||

|---|---|---|

| Model | NJP-1200D | NJP-3000D |

| Capacity | 72000caps/h | 165000caps/h |

| NO.of mould bores | 9 | 21 |

| Capsule Size | 000#-5# and safety capsule | 000#-5# and safety capsule |

| Power | 380/220V,50/60Hz,7KW | 380/220V,50/60Hz,11KW |

| Dimensions | 980*980*2100mm | 1610*1210*2180mm |

| Net Weight | 1000KG | 2200KG |

| SNR | <70dB | <70dB |

Remarks

- cGMP design with emphasis in powder dust handling: Enclosed main turn table avoid dust getting into mechanical parts.

- Automatic control for capsule and powder supply.

- PLC control for reliable operation. Touch Screen HMI, featuring user friendly controls: production counter, manual / automatic / parameter setup modes, alarms.

- Precision capsule segments and dosing disk minimizes adjustments following parts changeover.

- SS 304 stainless steel frames and transparent safety interlock guards.

Bewertungen

Best

Capsule production speed is super fast, I have never seen such a fast machine

From: Isabella | Datum: 01.03.2021 02:43

Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Containment Automatische Kapselfüllmaschine SFK-703

Containment Automatische Kapselfüllmaschine SFK-703

Verwandte Produkte

NJP-1200D Hohe füllende Genauigkeits-automatische Kapsel-Füllmaschine

NJP-2000C Automatisch Kapselfüllgerät Kapselfüllmaschine

NJP-3500C Automatisch Kapselfüllgerät Kapselfüllmaschine

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche