Introduction

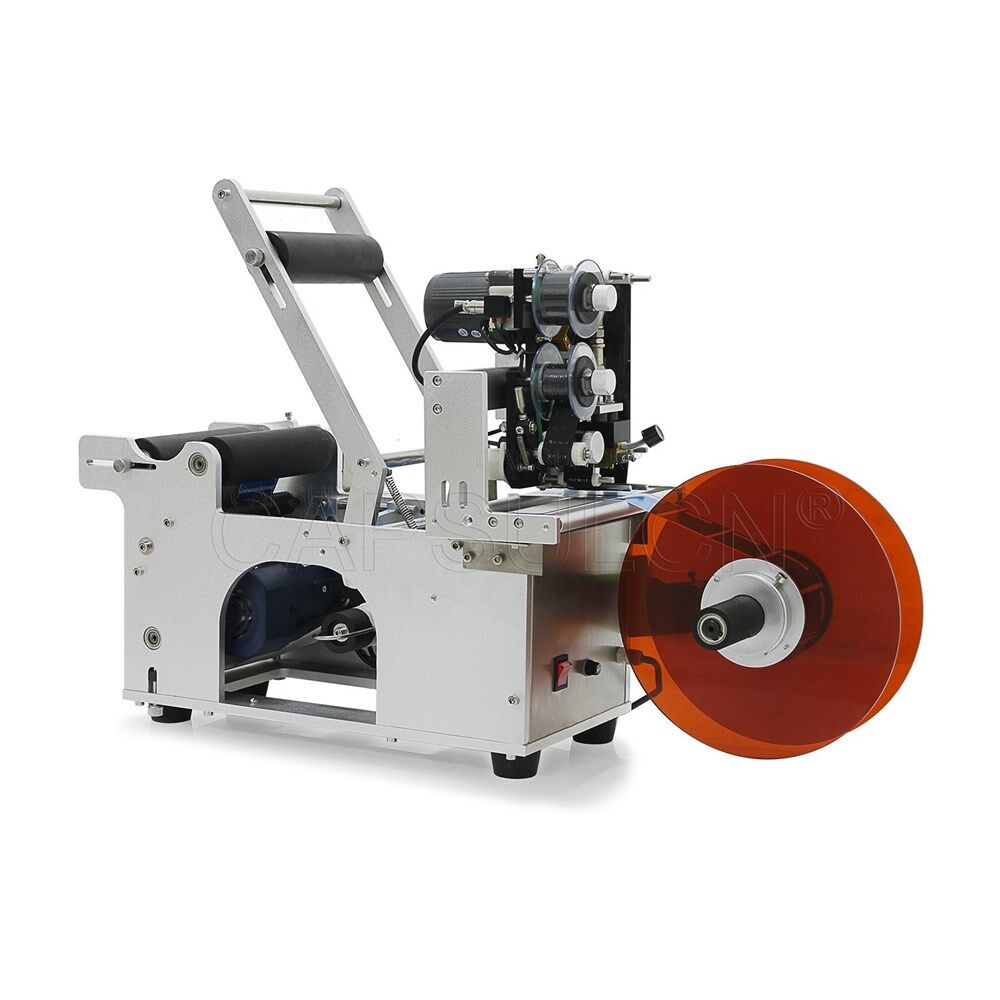

MT-50 Semi-Automatic Round Bottle Labeling Machine is a Label Machine for bottles,The machine is a table type semi-automatic machine with motor and touching control by limit switch and with small volume, which can be suitable for matching with the vertical filling packing machine and it is widely used in daily Chemical, food and beverage, medicine, chemical industry and other light industries.

Suitable for different size of adhesive label or adhesive film on all kinds of round bottle,round tank,round barrel to self-adhesive labeling,High accuracy and high speed.

The machine is applicable to round bottles of various sizes, and is suitable for pilot production. It only can be used independently, and cannot be added in production line.

Features

- The machine has a proper structure, reliable performance, and is easy to operate. It adopts photoelectric detection which guarantees labeling accuracy.

- Adopts advanced labeling mechanism to ensure the labeling precision.

- Adaptable, and is able to label bottles of various sizes.

- The label optical eye, of which the sensitivity is adjustable, can identify the backing paper of the label of varied transmittance, compare and adjust light sensitivity, and optimally adjust labels of different lengths to ensure smooth and correct labeling.

- Most of mechanism, including the frame, catch pin, and fastener, adopts stainless steel and aluminum profile that are rust-proof, free of pollution, and meets the GMP environmental requirements.

- All metal are made of 304 stainless steel with surface finishing and special treatment, which we can guarantee you very good quality.

This is standard configuration, if you need longer than this, contact us firstly, It will be customized.

Specifications

| Model | MT-50 |

|---|---|

| Labeling speed | 25-50pcs/min (depends on products and labels size) |

| Label size | (W)20-130mm/(L)30-280mm |

| Products diameter | Φ20-120mm |

| Label reel | Inner diameter 75mm/Outer diameter 250mm |

| Accuracy | ±0.5mm(depends on product and label size) |

| Voltage | 220V 50HZ/110V 60HZ |

| Machine size(L x W x H) | 650x300x545mm |

| Weight | 25kg |

| Power | 120W |

| Inner diameter of label roll | ≥75mm |

| Max outer diameter of label roll | ≤250mm |

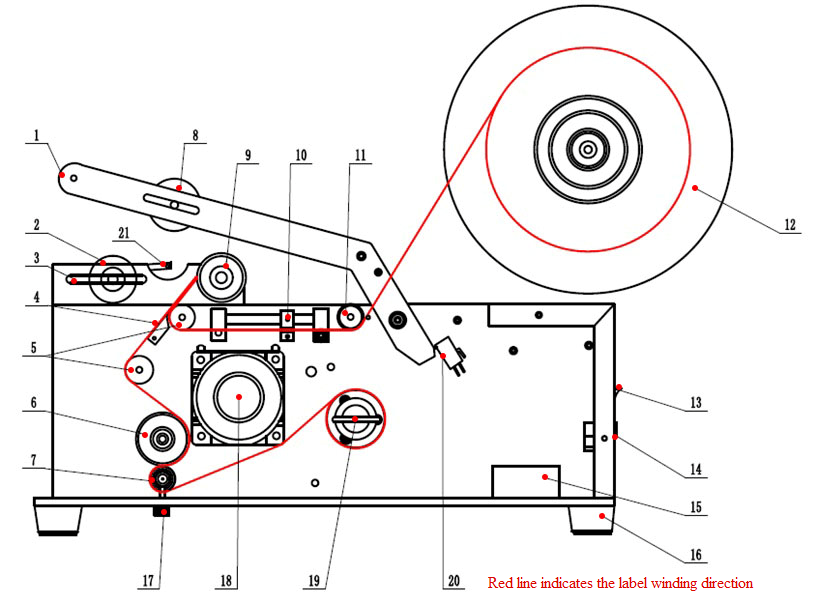

Detail diagram

| 1. Bottle pressing swinging arm | 2. Bottle supporting roller | 3. Bottle supporting stand |

| 4. Stripping plate | 5. Transition roller | 6. label pulling soft roller |

| 7. Label pulling knurl wheel | 8. Bottle pressing roller | 9. Labeling soft roller |

| 10.Label sensor | 11. Guide rod | 12. Paper supply tray |

| 13. Power switch | 14. Power socket | 15. Control module |

| 16. Footing | 17. Label pulling adjusting screw | 18. Label pulling motor |

| 19. Paper collecting wheel | 20. Microswitch | 21. Catch pin |

Troubleshooting

| Malfunction | Cause | Remedy |

| The label does not come out | Wrong position of the microswitch | Adjust the microswitch position |

| Failure of the microswitch | Replace the microswitch | |

| Label pulling knurl wheel does not press tightly against the label belt and cause slip when pulling the label | Fasten the label pulling adjusting screw | |

| Power is not switched on | Switch on the power supply | |

| The backing paper is broken | Re-ware the label according to the label winding diagram | |

| Label pulling motor breaks down | Replace the motor | |

| The chain wheel pin of the label pulling motor and label pulling soft loosen, and causes chain wheel rotation | Re-fix the chain wheel | |

| Label comes out continually | Wrong position of the label sensor, or labels do not pass through the detection position of the label sensor | Adjust the label sensor position |

| Label sensor beaks down | Adjust or replace the label sensor | |

| The label sensor sensitivity is higher or lower | Properly adjust the sensitivity of the label sensor | |

| Inaccurate position of the labeling axial | The front and back ends of the catch pin are not positioned | Fasten the catch pin |

| Position of the label on the label stripping plate is incorrect | Adjust the label position | |

| The bottom of the bottle did not stick to the catch pin when the bottle was put | Please put the bottle correctly | |

| The retaining ring of the guide band is not well fixed | Re-adjust | |

| Wrong position of the label on the paper supply tray | Re-adjust | |

| Label doesn’t stay | Reserved label is not long enough | Adjust the length of the reserved label |

| Inadequate viscosity between the surface of the object to be labeled and the label or excessive humidity | Replace the label or check the surface of the bottle | |

| Bottle pressing roller does not press against the bottle to be labeled, and the bottle fails to roll | Adjust the gap between two rollers for bottles | |

| Excessive gap between the labeling soft roller and the stripping plate | Adjust the gap | |

| Wrinkles after labeling | Reserved label is too long | Adjust the length of the reserved label to be shorter |

| Sundries on the bottle surface | Clean up the bottle surface | |

| Label stripping plate is too close to the labeling soft roller | Adjust the gap | |

| Larger misalignment of labels heads and label ends after rolling | Axles of the stripping plate and bottle to be labeled are not parallel | Adjust the position of the adjustable roller and stripping plate to make the bottle supporting roller and stripping plate parallel to labeling soft roller |

| Label belt tilts or it swings back-and-fro when pulling the label | Fasten the guide belt ring to prevent the label from swinging back and forth | |

| Excessive error of the diameter of the labeling area on the object to be labeled | Caused by the object itself | |

| Label stripping plate is too far away from the bottle or slightly touch the labelling soft roller | The normal condition shall be 1 mm | |

| Installation plate of the stripping plate is not fastened and vibrates during operation | Refasten the fastening screw | |

| Bottle is dirty or has water on it | Change to a dry and clean bottle |

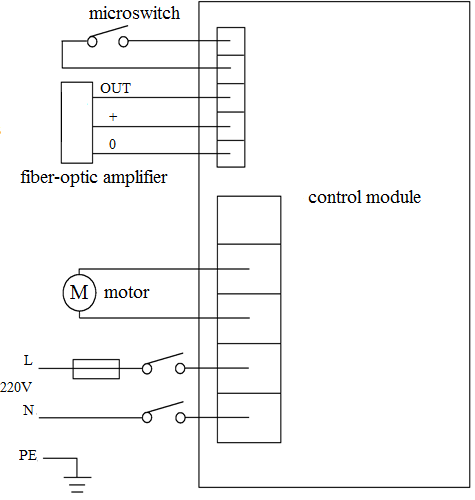

Electrical diagram

Bewertungen

good

This machine can be customized, I am using the universal version, I use this machine infrequently, but it is very useful in general

From: Gast | Datum: 11.10.2019 02:15

Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Containment Automatische Kapselfüllmaschine SFK-703

Containment Automatische Kapselfüllmaschine SFK-703

Verwandte Produkte

Automatische vertikale Etikettiermaschine vom Typ "Poked Roll" NCT-21100

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche