Introduction

Rotary sieve machine, often called rotary sifting machine, is a new high precision fine powder screening machine. It uses vertical vibration motor as excitation source. This motor is equipped on both sides with an eccentric hammer which functions to transfer the rotation movement of motor to horizontal, vertical and inclined motions. And the hammer then delivers the motions to screen surface for sifting. At present, rotary sieve machine is widely applied in pharmaceutical, foodstuff and other industries.

Rotary sieve machine is suitable for many industries.

- Chemical industry: resin, paint, industrial pharmaceuticals, cosmetics, herbal powder, etc.

- Food Industry: sugar powder, starch, salt, rice flour, milk powder, soybean milk, egg powder, soy sauce, juice, etc.

- Metal and metallurgy mining: aluminium , lead, copper, alloy and solder powder, ore, manganese dioxide, electrolytic copper powder, electric magnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy calcium carbonate, quartz sand, etc.

- Pollution treatment: waste oil, waste water, dyeing wastewater, additives, activated carbon, etc.

Specifications

| Model | XZS-800 |

|---|---|

| Nominal diameter | Ф800 |

| Effective screen diameter | Ф750 |

| No. of Plies | 3 |

| Vibration Motor | 0.75 |

| Maximum feed granularity | <30 |

| Vibration times (times / minutes) | 1500 |

| Packing Dimension(L x W x H) | 1040 x 1040 x 1250mm |

Remarks

- Rotary sieve machine has features of high efficiency, simple operation and small size. With high screening precision, it is suitable for all kinds of powdery and mucus materials.

- This rotary sifting machine is removable and only takes 3 to 5 minutes to change a net.

- Its screen is not blocked and produces little scattering dust. It can sieve 0 to 400 meshes of materials.

- Rotary sieve machine is well-designed and durable, which can work continuously.

- During the sieving process, coarse materials and impurities can be discharged automatically. The discharging direction can be adjusted along the circumferential direction.

- Rotary sifting machine can sieve materials on different layers (not more than 5) at the same time.

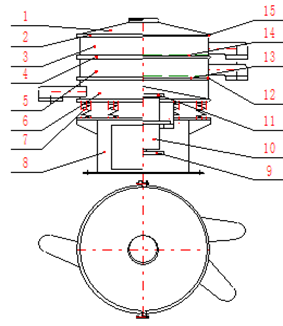

structure

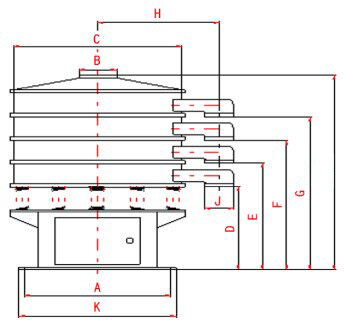

Size

|

Position | Size |

|

A |

700 |

|

|

B |

180 |

|

|

C |

800 |

|

|

D |

450 |

|

|

E |

600 |

|

|

F |

750 |

|

|

G |

900 |

|

|

K |

750 |

|

|

H |

580 |

|

|

J |

140 |

|

|

Single layer |

870 |

|

|

Double layer |

1020 |

|

|

Triple layer |

1120 |

Installation

Remove the transport support. Since the base of the screen and the screen frame are connected by springs, the upper half of the screen machine is firmly fixed by transport during transport. After entering the installation site, the transport support should be removed. It is strictly forbidden to take the test machine.

According to the structure diagram, carefully check the presence or absence of abnormal parts. If you have any abnormal parts, please contact capsulcn.

The sieve machine should be placed on a level basis when installing. In the absence of a foundation, an anti-vibration rubber sheet should be placed between the workbench and the base.

The cable in the vibration motor and the screen machine is subjected to severe vibration, and it should be connected to the standard ground wire for safety. There is no vibration in the ordinary motor structure cable.

Each layer of the vibrating screen can be rotated 360° horizontally. Loosen the locking ring bolts, adjust the required position of each layer of discharging nozzles, and then remember the locking ring bolts. The method of tightening is to use a hardwood rod or a rubber hammer to hammer the periphery of the outer circumference of the locking ring while the upper nut is on the side until the hammering sound is not loose.

Test

Close the power switch and run it for 20-30 minutes. The motor should normally run clockwise. If the direction is wrong, please adjust the three-phase power supply.

It should be confirmed that the vibration motor or the ordinary motor operates within the rated current. When starting the operation, especially at low temperatures, the current will be slightly higher, but within 20-30 minutes, it should be reduced to the rated current value.

The machine must not have abnormal sounds. If abnormal sounds occur, it should be shut down quickly for inspection. The abnormal sound is usually caused by the loosening of the fastening parts. Especially when reassembling after transportation and disassembly, pay special attention to the fastening of each part. The machine has an instantaneous resonance zone (1-2 seconds) when starting and stopping, and the amplitude and noise are obviously increased at this time, which is a normal phenomenon.

After the idling, a small amount of material can be introduced into the sieve machine through the feed port, and then slowly increased to the required and acceptable feed amount. At this time, the weight should be adjusted according to the mesh discharge condition, so that The efficiency of the sieve machine is at its best.

This series of sieve machines generally do not have a bouncing ball device to meet the screening requirements. Special materials need to be equipped with a bouncing ball device designed and installed separately, and the idling noise will increase.

Precautions

The feeding amount is subject to the processing capacity of the equipment, and too much feeding at one time hinders the normal movement of the material on the screen surface, which not only makes the screen fatigue become loose, but also greatly reduces the material handling amount. When a large amount of material is given at one time, the load of the motor itself that is in an unbalanced operation suddenly increases, causing damage to the motor and reducing the life of the motor. If the amount of feed does not reach the processing capacity of the equipment, it is wasted energy and reduced production.

The feeding method with strong impact must be equipped with a buffer hopper. The material directly impacts the mesh surface, which not only consumes the vibration force generated by the vibration source, but also easily causes the mesh surface to be damaged, which affects the quality of the output and the screening filtration.

Maintenance

Carefully check the bolts at each joint of the machine for looseness. If it is loose and continues to operate, it will cause damage to the machine.

Whether the wiring from the vibration motor or the ordinary motor to the switch is worn or not.

Check the motor or vibrator for abnormal sounds and abnormal heat. The temperature limit of the bearing part is 40 °C higher than the ambient temperature. If it is abnormal, add lubricating oil (molybdenum disulfide grease, dropping point ≥200 °C), or replace the bearing. The checking of the motor should be carried out by a skilled technician.

Whether the screen is tensioned, whether the mesh surface is damaged, if there is damage, change the net in time.

The machine must be cleaned up after each use.

Bewertungen

Powder Sifter Machine

The powder selected by the rotating machine is very fine and uniform. A good machine. I think this should be one of the best machines on the market.

From: Jack | Datum: 01.03.2021 02:05

Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Containment Automatische Kapselfüllmaschine SFK-703

Containment Automatische Kapselfüllmaschine SFK-703

Verwandte Produkte

SY-200 Pulver Sifter Maschine

SY-300 Pulver Sifter Maschine

XZS-600 Pulver Sifter Maschine

XZS-800 Pulver Sifter Maschine

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche