Introduction

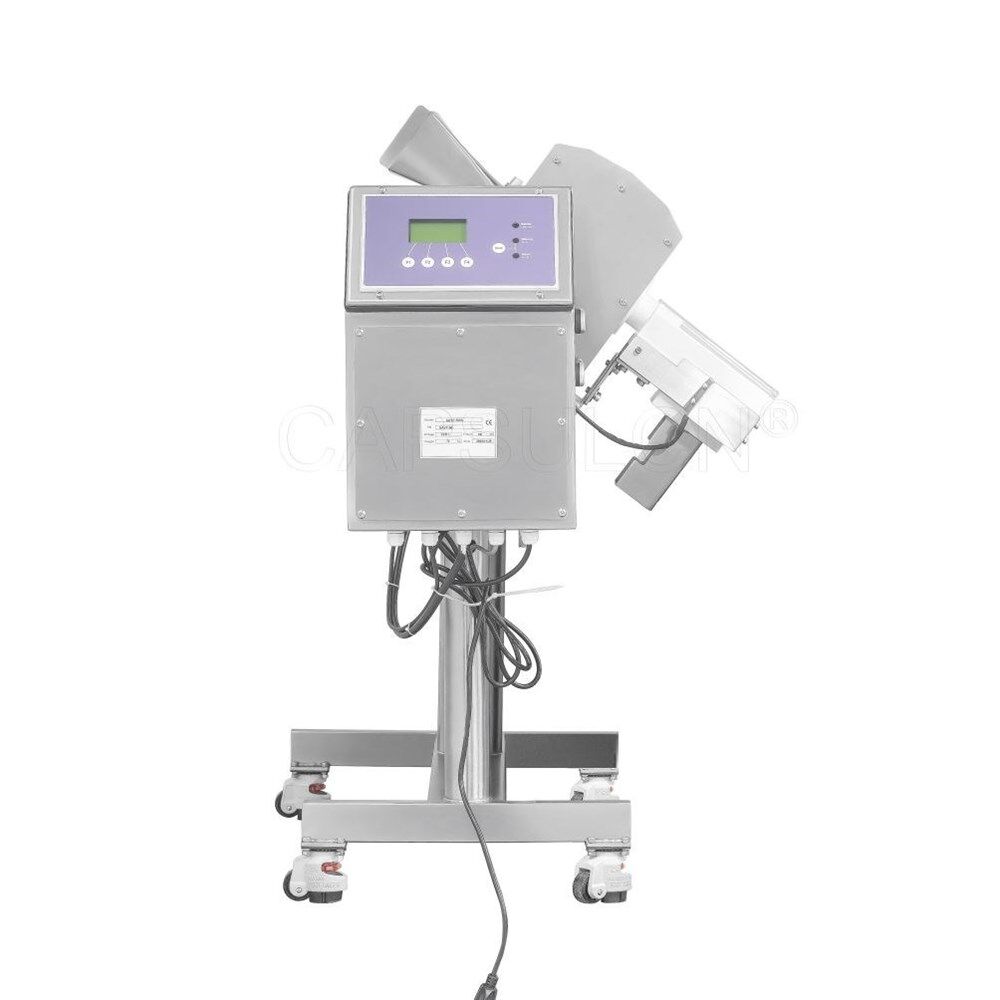

The metal separator is mainly used for the detection and separation of metal impurities in gravity feed granular materials in plastic chemical industry as well as other similar industries.

It can detect all magnetic and nonmagnetic metal impurities (e.g.: steel, stainless steel, aluminum, etc.). Even if encapsulated, these metal impurities can still be detected and then separated by the rejecting unit.

Specifications

| Model | SAYP-700S |

|---|---|

| Caliber of feeding inlet | Φ35mm |

| Detection accuracy | Φ0.3mm |

| Capacity | 10,000-15,000 pcs/min |

| Working voltage | AC220V±10%, 50-60Hz (Customizable AC110V/ AC380V) |

| Ambient temperature | -10℃ - +80℃ |

| Discharge time | 0.3~5s (Adjustable) |

| Compressed air | 4~7 Bar |

Remarks

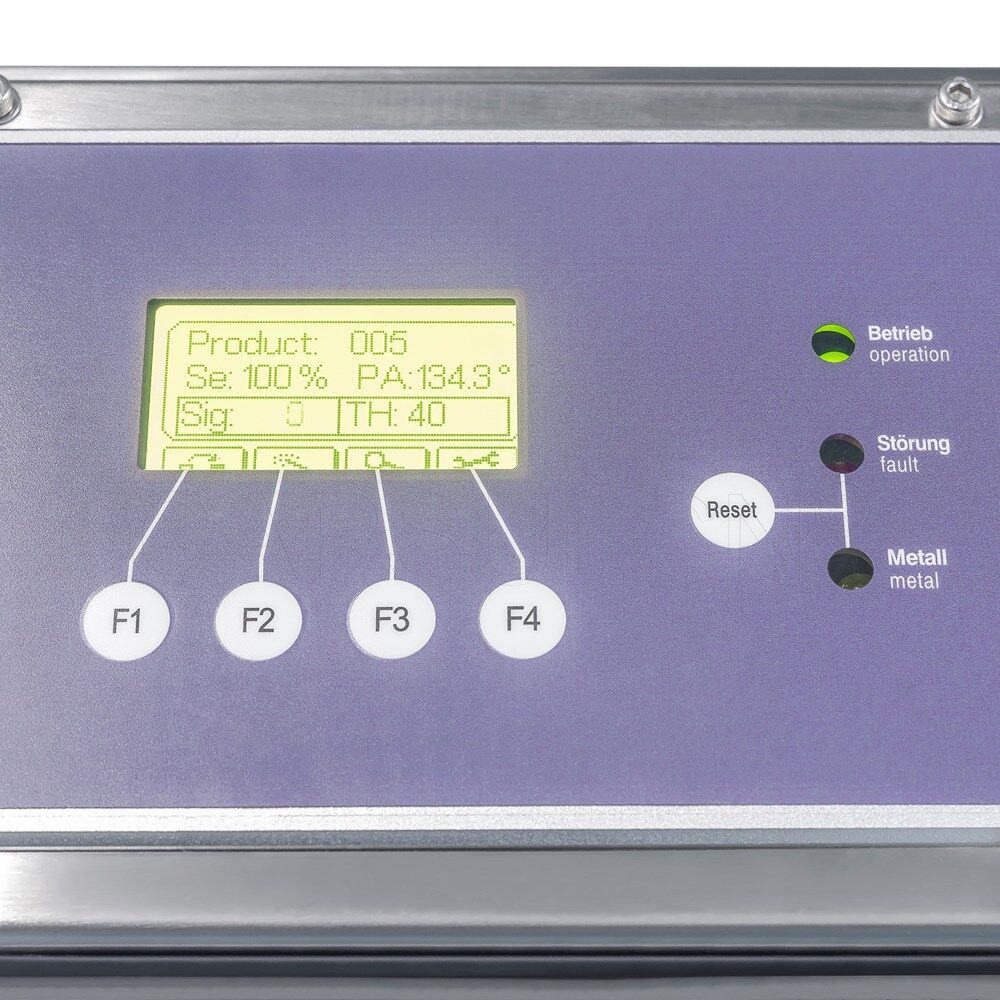

- Special structural design can effectively help avoid the interference of external factors such as vibration, noise and product effect.

- With German technology and ultrahigh detection accuracy, it is a metal separator specially designed for medicine and health product industries.

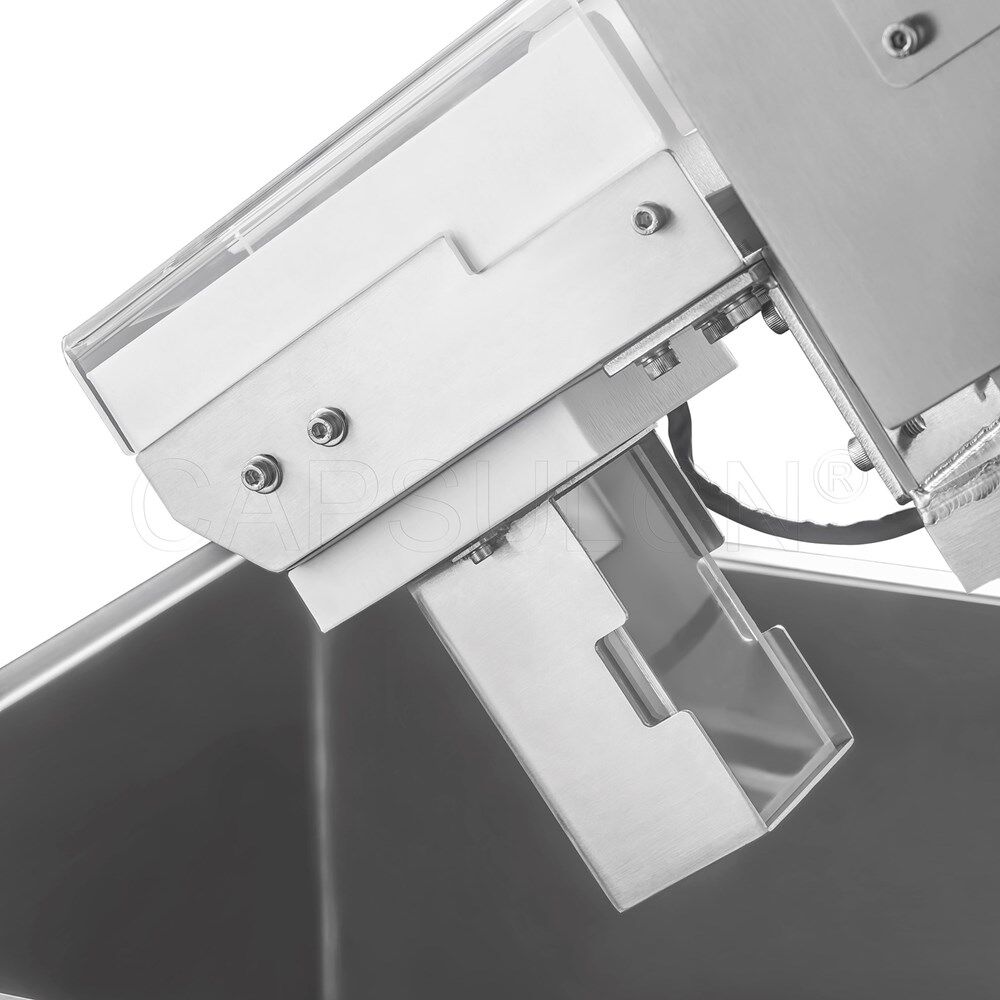

- The ejecting unit is made of 316 stainless steel, so it is easy to dismantle and clean. It can meet the FDA and USDA certification requirements.

- It can work in conjunction with other equipment to ensure the normal operation of the production line. The height and tilt angle of the rack can be adjusted manually, which makes it easy to move and clean.

- Unique accuracy can detect tiny metal objects in drugs, and the processing speed can reach about 15,000 pcs/min.

Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Big Promotions

Containment Automatische Kapselfüllmaschine SFK-703

Offerte anfordern

Containment Automatische Kapselfüllmaschine SFK-703

Offerte anfordern

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche