Let the machine work for you!

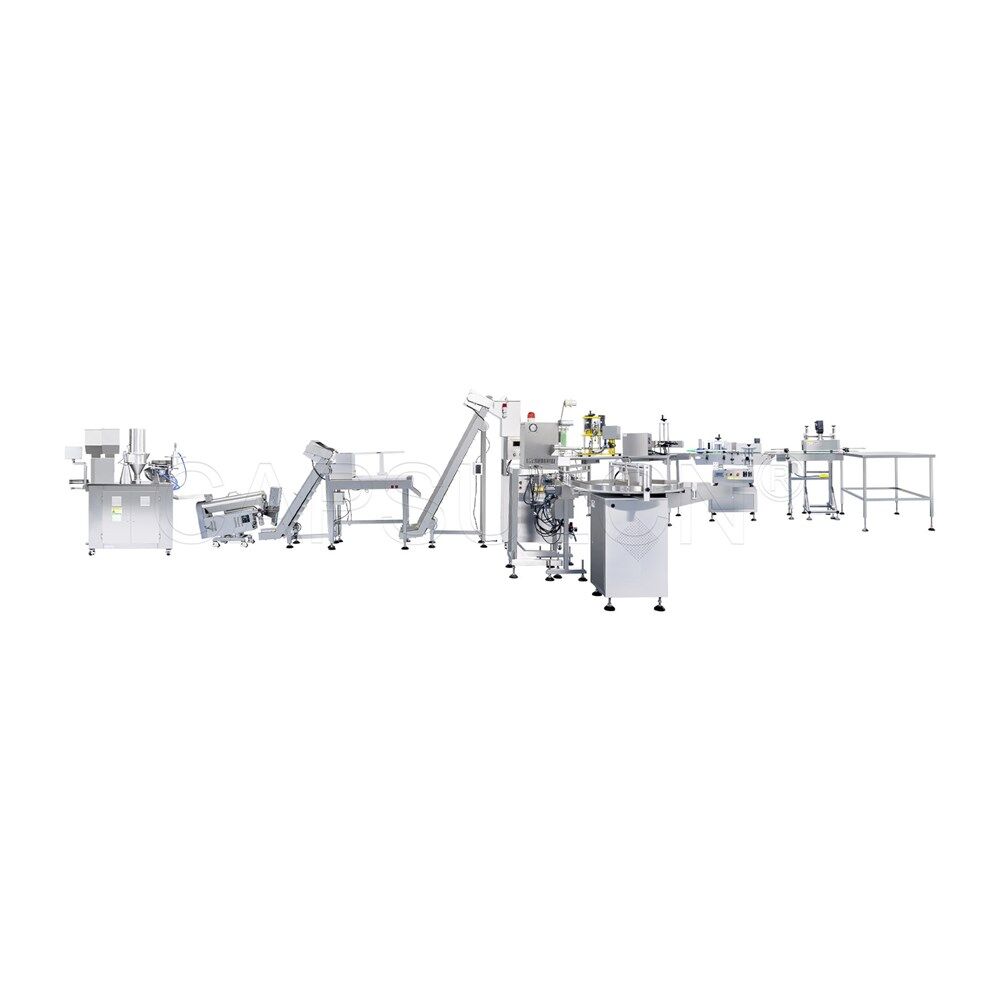

Eleven machines cooperate perfectly

* You can choose the complete line or just several machines of it, which is based on your own needs.

* As each machine cooperates perfectly in order, it greatly improves not only the efficiency but also the quality and grade of product packaging.

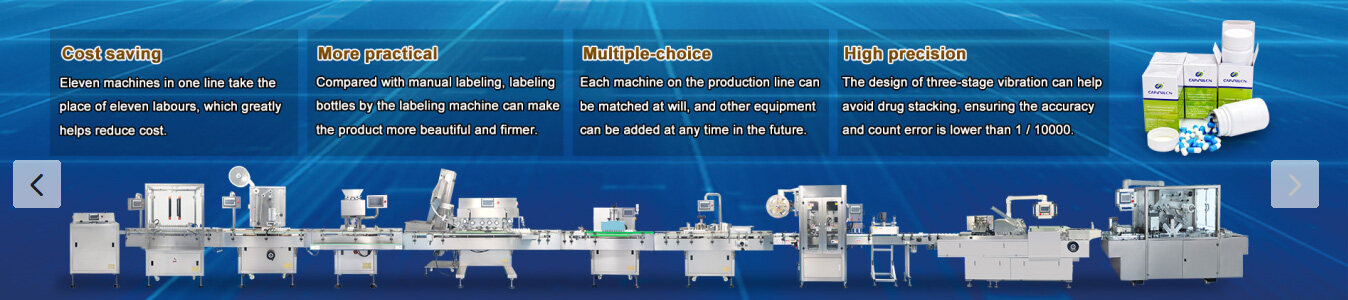

Cost saving

Eleven machines in one line take the place of eleven labours, which greatly helps reduce cost.

More practical

Compared with manual labeling, labeling bottles by the labeling machine can make the product more beautiful and firmer.

Multiple-choice

Each machine on the production line can be matched at will, and other equipment can be added at any time in the future.

High precision

The design of three-stage vibration can help avoid drug stacking, ensuring the accuracy and count error is lower than 1/10000.

Introduction

- Bottle Unscrambler—Bottle Cleaning—Desiccant Inserter—Counter—Capper—Induction sealer—Labeler—Cartoner—Overwrapper

- Designed to comply with FDA and cGMP regulations

- Different capacity ranges from 30BPM to 200BPM

- Customize your own counting line

Specifications

| Model | PBDS-8 | PBDS-12 | PBDS-16 | PBDS-24 |

|---|---|---|---|---|

| Production capacity | 10~50 bottles per minute | 20~55 bottles per minute | 60-100 bottles per minute | 80-150 bottles per minute |

| Container size | Dia.:20~100mm Height:50-100mm |

Dia.:20~100mm Height:40~200mm |

Dia.:20~100mm Height:40~220mm |

Dia.:20~100mm Height:40~220mm |

| Size of capsule/tablet | Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

Caps: #00-#4 Tablets:Ф5.5-22mm |

| Main Power | 0.4kw | 1.5kw | 1.5kw | 1.7kw |

| Power Supply | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz | 110V 60Hz / 220V 50Hz |

| Weight | 280kg | 300kg | 360kg | 580kg |

| Overall Dimensions | 1600x1500x1600mm | 1600x1500x1600mm | 2600x1600x1600mm | 4200x1800x1600mm |

Remarks

- With special patented flap partial filling system ,the discharging of medicine is homogeneous and stable without damage.

- Adopting the anti high dust photoelectric sensing technology, it also can work stably under the high dust circumstance.

- Photoelectric sensor can check automatically if there’s no bottle and stops automatically.

- Easy to operate, disassembly, clean and change the components without any tools.

- Adopting intellectualized design, all kinds of operation data can be set according to the requirement. It can store 10 groups of setting parameters for use.

Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Containment Automatische Kapselfüllmaschine SFK-703

Containment Automatische Kapselfüllmaschine SFK-703

Verwandte Produkte

Tablet- und Kapselzählmaschine mit mehreren Kanälen

Automatische vertikale Etikettiermaschine vom Typ "Poked Roll" NCT-21100

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche