Schreiben Sie Ihre eigene Bewertung

Bietet Auch

Big Promotions

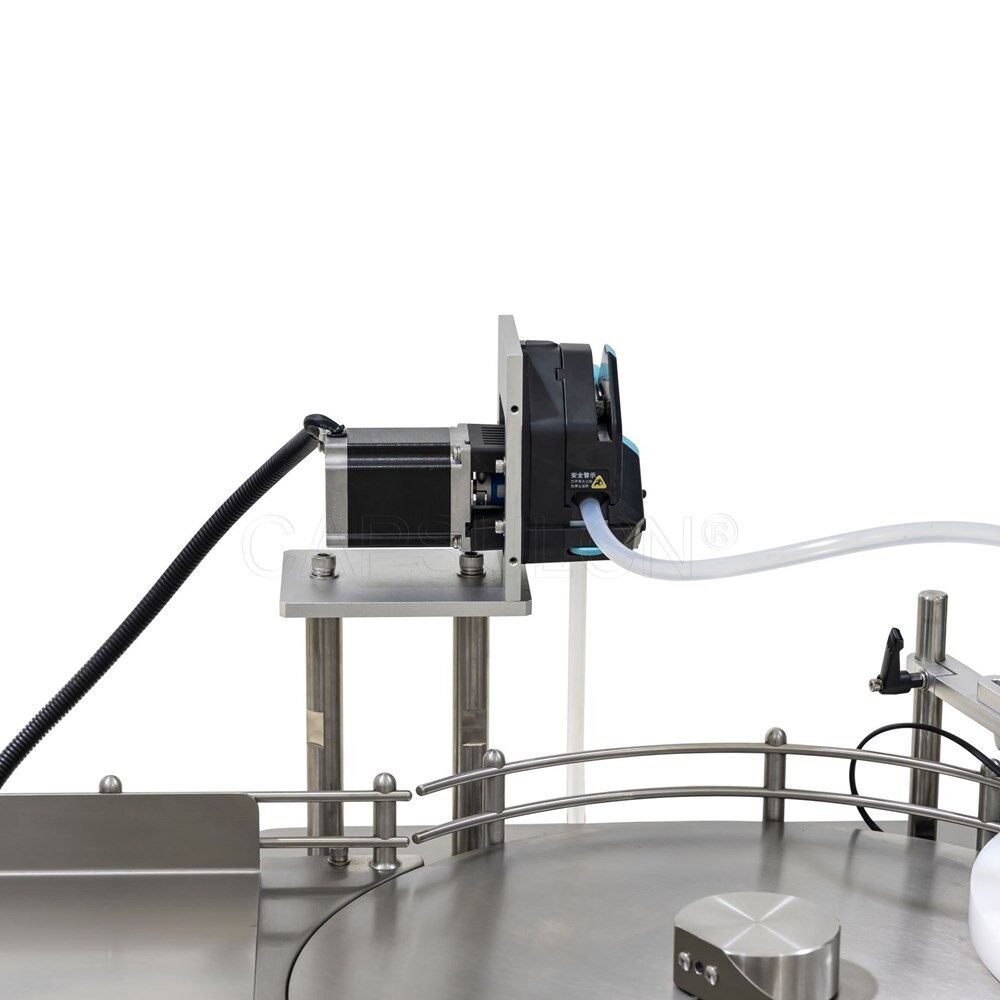

Containment Automatische Kapselfüllmaschine SFK-703

Offerte anfordern

Containment Automatische Kapselfüllmaschine SFK-703

Offerte anfordern

Our Team

As an expert in the pharmaceutical and pharmaceutical packaging industry, iPharMachine has provided solutions for hundreds of pharmaceutical and health product manufacturers for 17 years. By visiting customers, we get good reviews from our customers.

- info@ipharmachine.com

- English Español Deutsche